GRAPHENE

The novel design, detailed in the journal ACS Nano, roughly doubles the amount of electrical energy the rapid-charging devices can hold, helping pave the way for eventual use in everything from smartphones and laptop computers to electric vehicles and high-powered lasers.

"We're showing record numbers for the energy-storage capacity of supercapacitors," said lead researcher Michael Pope, Professor at the University of Waterloo in Canada.

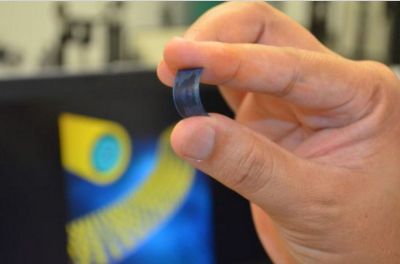

To boost the storage capacity, Pope and his team developed a method to coat atomically thin layers of a conductor called graphene with an oily liquid salt in supercapacitor electrodes.

The novel design, detailed in the journal ACS Nano, roughly doubles the amount of electrical energy the rapid-charging devices can hold, helping pave the way for eventual use in everything from smartphones and laptop computers to electric vehicles and high-powered lasers.

"We're showing record numbers for the energy-storage capacity of supercapacitors," said lead researcher Michael Pope, Professor at the University of Waterloo in Canada.

To boost the storage capacity, Pope and his team developed a method to coat atomically thin layers of a conductor called graphene with an oily liquid salt in supercapacitor electrodes.

Existing commercial supercapacitors only store enough energy, for example, to power cellphones and laptops for about 10 percent as long as rechargeable batteries.

The researchers working on the project used an oily liquid salt which works as a spacer to separate the thin graphene sheets, preventing them from stacking like pieces of paper which eventually increases their exposed surface area - a key to maximising energy-storage capacity.

Smartphone screens seem to crack at the slightest breeze, but researchers at the University of Sussex might have developed a hardier alternative. The secret ingredient is (as usual) graphene, and when combined with silver nanowires the new material could lead to touchscreens that are tougher, easy to manufacture, more responsive, less power-hungry, and even flex and bend.

Your smartphone screen most likely gets its touch input from a layer of indium tin oxide, but while the material is great for its transparency and conductivity, it's also relatively rare, expensive and fragile. Silver is often used as an alternative but it's also a little on the pricey side, and we've also seen copper crop up in the past.

The Sussex team found that they could greatly reduce the amount of silver used by combining it with graphene – sheets of carbon just one atom thick. To make the screen, the researchers float the graphene film on the surface of water, then pick it up with a rubber stamp and press it on top of a layer of silver nanowire. While this technique sounds like a craft project for now, the team says it lends itself well to being scaled up, using spraying machines or patterned rollers.

"The addition of graphene to the silver nanowire network also increases its ability to conduct electricity by around a factor of ten thousand," says Alan Dalton, head of the team behind the material. "This means we can use a fraction of the amount of silver to get the same, or better, performance. As a result screens will be more responsive and use less power."

According to the researchers, the benefits of using graphene go beyond lowering the cost of touch-sensitive film.

"One of the issues with using silver is that it tarnishes in air," says Matthew Large, lead researcher on the project. "What we've found is that the graphene layer prevents this from happening by stopping contaminants in the air from attacking the silver. What we've also seen is that when we bend the hybrid films repeatedly the electrical properties don't change, whereas you see a drift in the films without graphene that people have developed previously. This paves the way towards one day developing completely flexible devices."

“That is the really cool part of this,” Pope said. “It’s a clever, elegant design.”

Increasing the storage capacity of supercapacitors means they can be made small and light enough to replace batteries for more applications, particularly those requiring quick-charge and quick-discharge capabilities.

Though supercapacitors are unlikely to ever attain the full storage capacity of batteries, they have the potential to conveniently and reliably power consumer electronic devices, electric vehicles and systems in remote locations like space.

“If they’re marketed in the correct ways for the right applications, we’ll start seeing more and more of them in our everyday lives,” Pope said.

That is slowly changing. “The ability to charge cellphones in seconds is one step closer,” the team said.

The university experts, led by professor of chemical engineering Michael Pope, have developed a new method that coats thin layers of a conductor called graphene with an ‘oily liquid salt’ in the supercapacitor’s electrodes – boosting its overall capacity.

Increasing the storage capacity of supercapacitors means they will soon be made small and light enough to replace traditional batteries.

“We’re showing record numbers for the energy-storage capacity of supercapacitors,” said Pope. “The more energy-dense we can make them, the more batteries we can start displacing.”

Pope said supercapacitors could displace lead-acid batteries in cars very soon, but long-term they will help to power smartphones and laptops.“If they’re marketed in the correct ways for the right applications, we’ll start seeing more and more of them in our everyday lives,” he said. The paper was published in the journal ACS Nano.

Pope’s team is far from the only scientific group working on the technology.

In November last year, experts from the University of Central Florida’s NanoScience Technology Centre developed a new process for creating “flexible supercapacitors” that could store more energy and be recharged more than 30,000 times without degrading.

“If they were to replace the batteries with these supercapacitors, you could charge your mobile phone in a few seconds and you wouldn’t need to charge it again for over a week,” said Nitin Choudhary, a UCF associate who spearheaded much of the cutting edge research.

No comments:

Post a Comment